1.Advantage for multi-port tube cooling plate

🔺It can be used in battery liquid cooling systems as well as battery direct cooling systems.

🔺There is no need to open an expensive stamping die. Only the cost of an extrusion die is required.

🔺Can cut the multi-ports tube into different lengths to make coolers of different lengths.

2.BOM for battery flat tubes cooler

3003 aluminum alloy is used. See the BOM below with parts name.

| Parts name | Material | Quantity | Dimension |

| multiport extruded aluminium tubes | AL3003 | 2 to 8,depend on design | Width from 20 to 100mm,height of 2.8~10mm |

| Manifold | AL3003 with 4343 or 4045 | 2 | Inlet & outlet &int, round and square shape.16×16 or 20×20 is most used |

| aluminum end cap | AL3003 with 4343 or 4045 | 4 | 1 to 2mm thick placed at the end of manifold for sealing |

| Nozzle pipe | AL3003 | 2 | For quick connection to coolant tube |

| bracket | AL3003 | 2 | 1.5 to 2mm thickness,custom design |

3.Multiport tube extrusion

🔺Multiport extrusion tube is produced using an extrusion die, and the mold opening cycle is about 10 to 20 days.

🔺We’ll check the wall thickness, height, width and straightness for the aluminum extruded tubes.

4.Aluminum manifold extrusion and stamp

We have regular aluminum manifolds in stock in round and square sizes, 16×16 and 20×20, with a wall thickness of 1.2mm.

After the manifold is extruded, it is necessary to punch out the grooves where the multi-port tubes fit insert.

5.Aluminum bracket

aluminum brackets mounting on manifold for positioning.This aluminum standoff bracket is made of aluminum alloy 3003 and is processed by CNC machining or stamping.

6.Aluminum end cap

The function of the end cap is to seal the ends of the manifold to ensure a tight seal. The end cap is generally designed from 1mm or 1.2mm thick AL3003+ double side 5% 4043 clad, which is stamped.For small batch, the aluminum end cap can be made by CNC.

Key takes away:

The aluminum end cap and manifold must have an interference fit, otherwise the brazing area will easily leak.

7.Flux spray on multiport tube cooler

In order to remove the oxide layer on the surface of the 4343 clad, it is necessary to spray a brazing flux on the surface of the manifold and end cap with a 4045/4343 composite layer. The component of the brazing flux is potassium fluoroaluminate. The purpose is to remove the oxide layer before the 4045/4343 composite layer is melt in brazing oven.

The parts of the Multiport tube cooler that require flux spraying are the manifold and aluminum end cap.

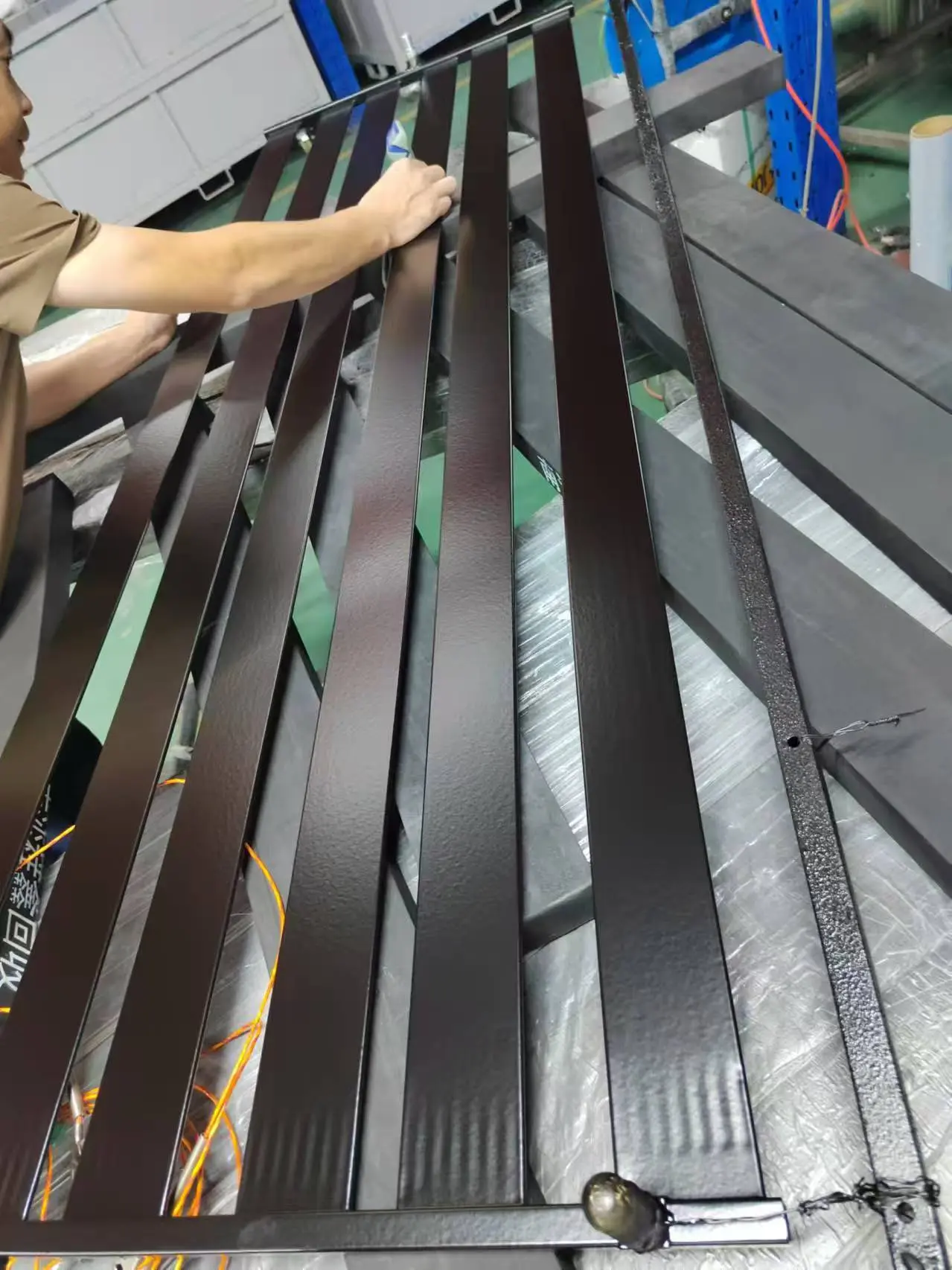

8.Multiport extruded aluminium core assemble

First, assemble the multiport tube and manifold, paying attention to the tube insertion depth and the core’s OA size.

Then, assemble the end cap and manifold, need to check the assembly gap, if big gap is detected, it’s re-commanded to applying solder paste to ensure a good brazing joint.

After the core is assembled, the OA dimensions need to be 100% measured. Then it is placed in the brazing fixture and prepared for the next step of brazing.

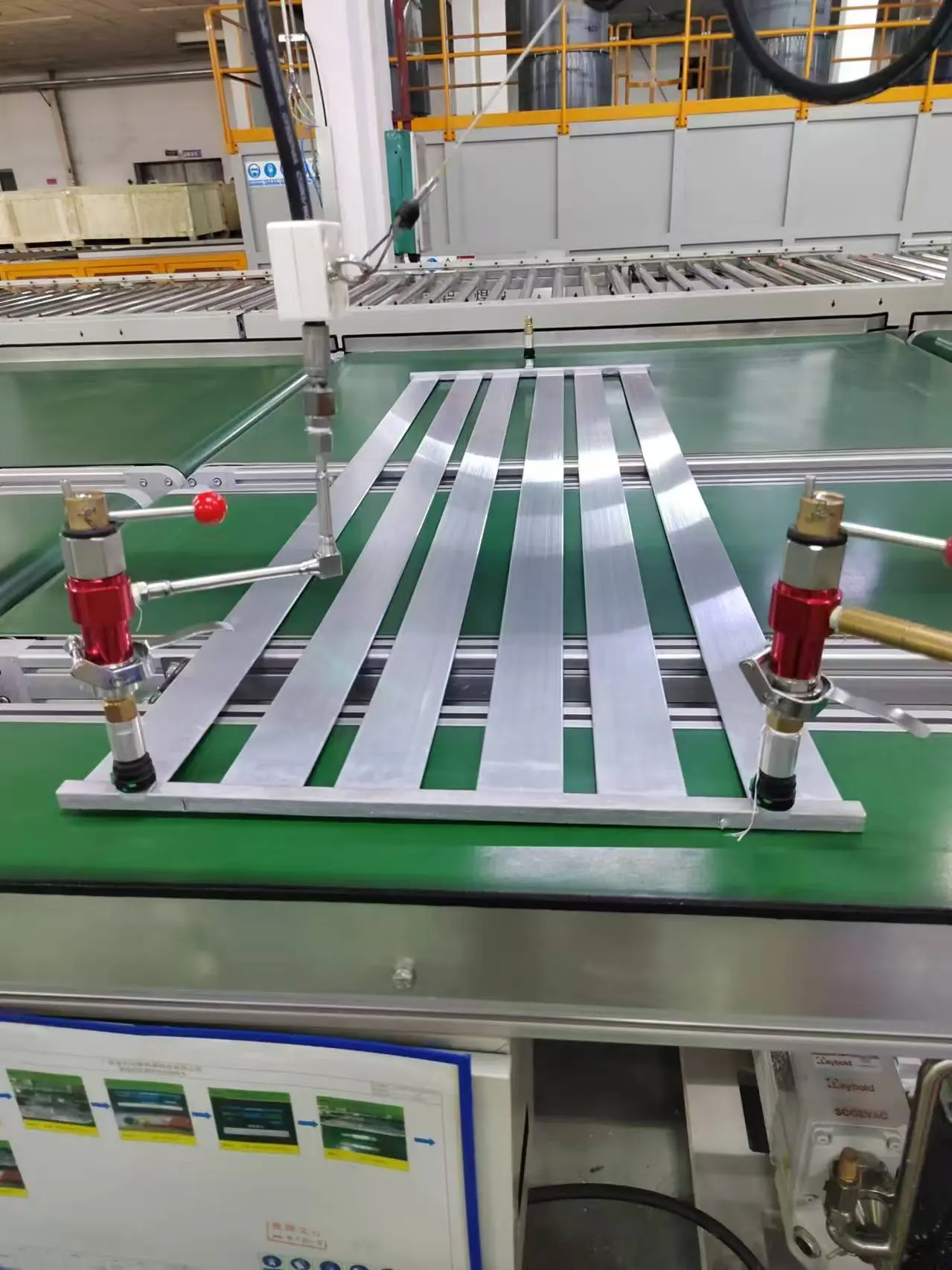

9.Brazing multiports tube cooling plate in OVEN

Brazing is performed in a tunnel furnace using a pre-set brazing program. The process includes degreasing, drying, brazing, cooling, and cold plate brazing before exiting the furnace. The entire process takes approximately 30 minutes.

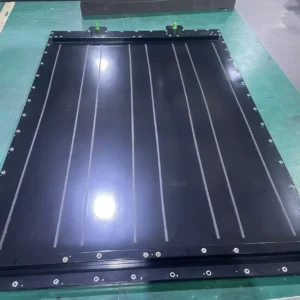

10.Leak test on multiport tubes cooling plate

After the multiport tube cooling plate is coming out from the furnace, it is transported to the helium testing station via a belt. For liquid-cooled cold plates, we use a leak test pressure of 250kPa and a leakage rate of 50Pa. The specific leak test requirements are mainly from customer requirement.

11.Quality inspection on multi-port tube cooling plate

Flatness is a key inspection parameter. For our muliport tube coolers, we internally control the flatness in the free state to be below 3mm. Furthermore, we perform position and profile dimensional inspections to ensure that the customer’s installation dimensions meet the drawing requirements.

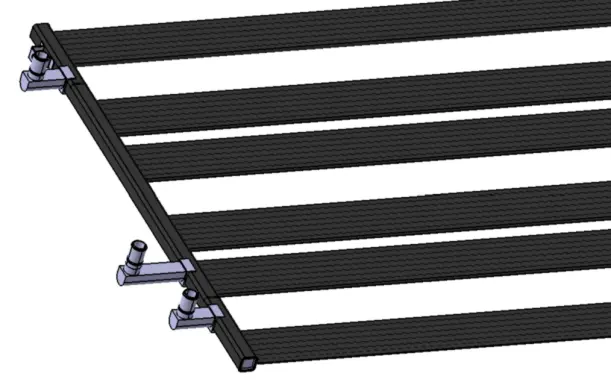

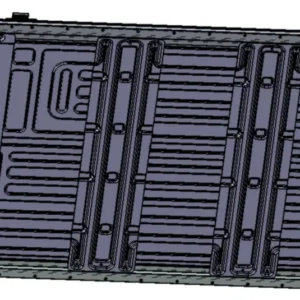

12.CAD design for multi-port tube cooling plate

Our professional design team help custom to do the 3d design cooler.. We design subcomponents such as the multi-port tube and end cap, as well as the overall cooler in 3D digital models and 2D drawings base on customer input. We then provide the customer with an STP digital model and PDF 2D drawings for approval.

Key take away:

Our team has 14 years of design and manufacturing experience. We try to use existing parts as much as possible to save mold costs and quickly deliver design digital models and drawings.

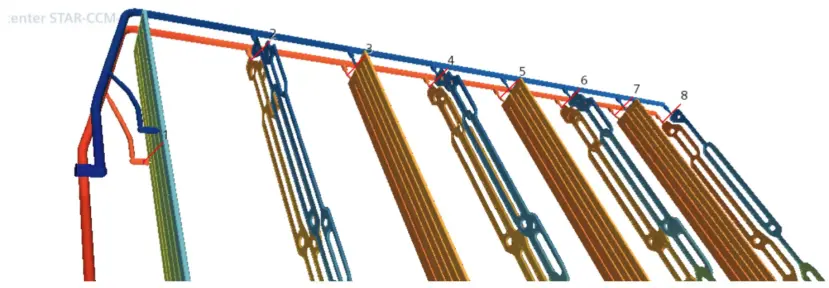

13.CFD simulation for MPT cooling plate

In addition to manufacturing and digital model design, we can also assist customers with CFD simulation analysis of MPT cold plates. With CFD simulation, we can help customers distribute flow and achieve optimal cooling effects.

More other type coolers find here:

Reviews

There are no reviews yet.