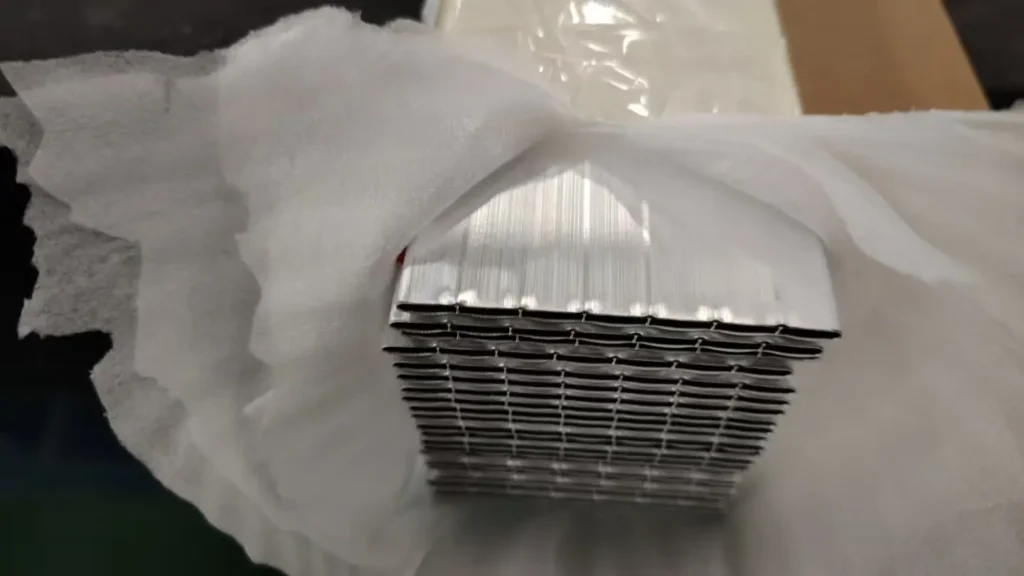

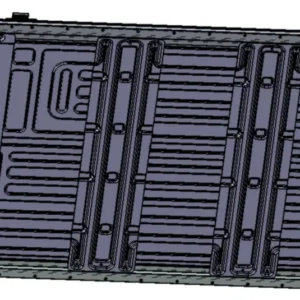

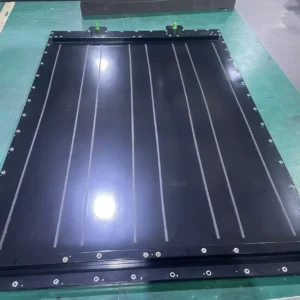

1.Example of custom Extruded Aluminum Cold Plate

A Liquid Cold Plate (LCP) is a key thermal management component that uses an internal fluid loop to remove heat. For example, a typical aluminum LCP with a serpentine channel is embedded into an electric vehicle’s battery pack. As coolant flows through these extruded channels, it efficiently absorbs heat from high-power battery cells, maintaining optimal temperature, ensuring safety, and prolonging battery life. This direct cooling method offers superior performance compared to traditional air cooling.

2.Liquid cold plate material

Typically, 3003-H112 aluminum alloy is used. Micro-channel tubes are extruded. Water nozzle are also typically made of 3003 aluminum and processed using CNC.

3.Battery cold plate manufacturing process

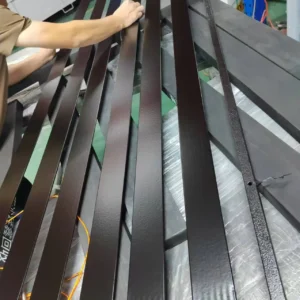

3.1 Cold plate tube extrusion

The cold tubes are produced by extrusion to produce long strips of tubes, which are then broken into certain length specifications.

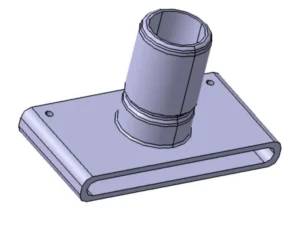

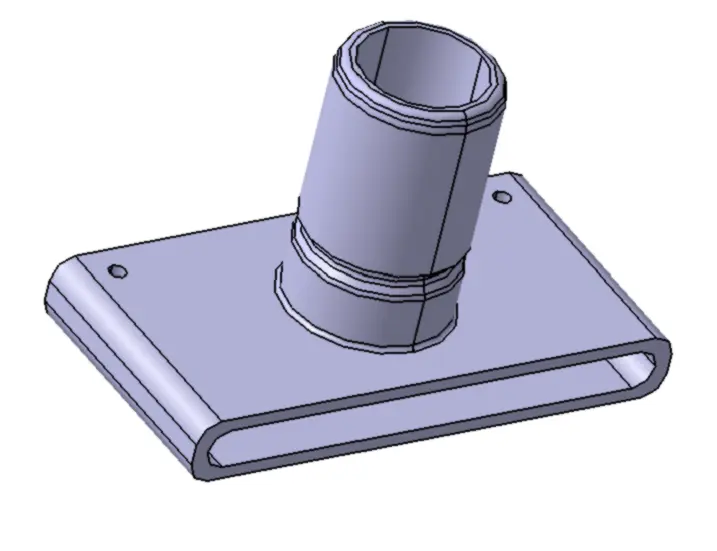

3.2 Battery cold plate water nozzle CNC machining

machined according to the designed 3d model, and then remove burrs.

3.3 Assembling welding ring for battery cold plate

The joint between the faucet and the Micro-channel tube is assembled with a welding ring.

3.4 Tunnel furnace brazing for battery liquid plate

Brazing is performed in a tunnel furnace using a pre-set brazing program. The process includes degreasing, drying, brazing, cooling, and cold plate brazing before exiting the furnace. The entire process takes approximately 30 minutes.

3.5 Air leak test for battery cold plate

Use air or nitrogen for testing, the test pressure is generally 250kPa, the leak detection time is 60s, and the leakage volume is less than 30Pa.

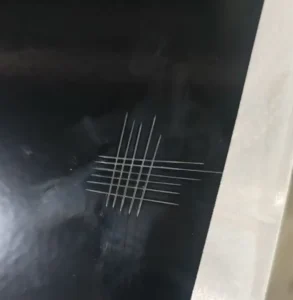

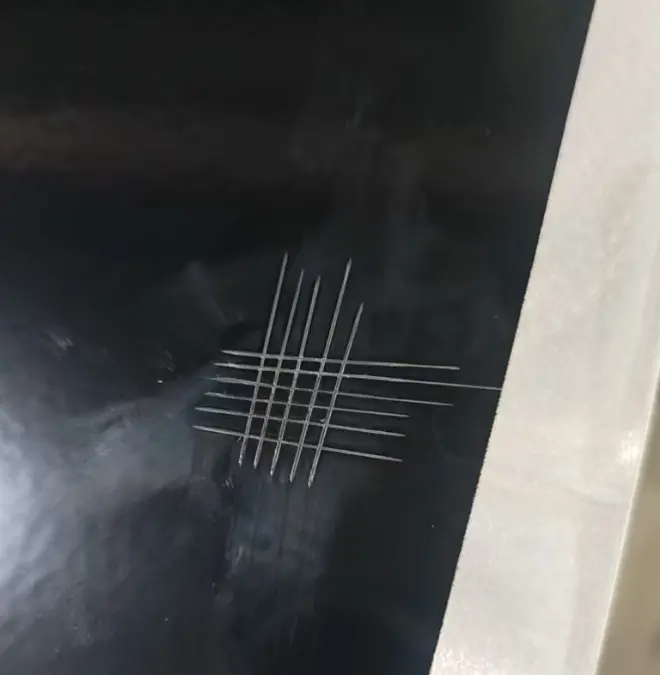

4 Powder spraying on battery cold plate

According to customer requirements, we make epoxy resin coating on the battery cold plate for corrosion resistance.After coating, we need to perform grid test on epoxy resin coating.

5 Quality inspection on battery cold plate

Carry out relevant drawing dimension inspection and flatness inspection.And perform the insulation withstand voltage test for coated battery cooling plate.The insulation resistance is greater than 500 megohms. The withstand voltage leakage current is less than 1 mA under 2700VDC.

Reviews

There are no reviews yet.