1.Why ESS is good and why need a cooling plate for ESS

⭐Battery energy storage system for solar is a clean energy source,and free cost. Many countries are now develop the solar ESS for CO2 reduction, and for peak shaving.

⭐Many cases such 5 mwh battery energy storage system is developed ok in used. To improve the battery energy storage system service lifetime, it’s must to use a battery cooling, cause temperature has a great impact on the lifetime of the ESS battery cell.

⭐The cooling plate for battery energy storage is to keep the cell temperature within a certain range to make sure a safe operation condition,especially to prevent catching on fire.

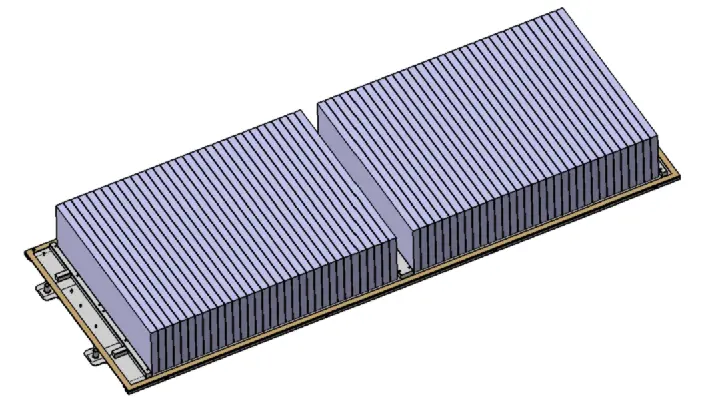

2.Cold plate integration in energy storage cabinets

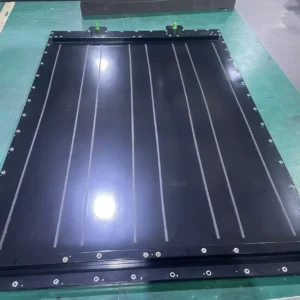

In current battery energy storage design example, the top of an ESS cooling plate is filled with prismatic cells, supported by a steel frame at the bottom. The frame is also made of rolled steel or extruded aluminum 6061-T6. This is designed like a tray, similar to a drawer placed on a shelf. At the bottom of ess cooler there will be filled coated with polyurethane foam.

3.BOM for battery energy storage cooling plate

3003 aluminum alloy is used. See the BOM below with parts name.

| Parts name | Material | Quantity | Dimension |

| Flat plate | AL3003 | 1 | 1.2 to 1.5mm thickness,with epoxy resin coating |

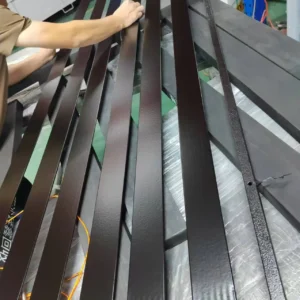

| Channel plate | AL3003 with 4343 or 4045 | 1 | 1mm thick, stamp with liquid flow channel pattern |

| Nozzle pipe | AL3003 | 2 | For quick connection to PA12 distribution tube |

| bracket | AL3003 | some | 1.5 to 2mm thickness,custom design for position |

4.Flat plate for ess battery cooler

Flat plate does not have the characteristics of flow channel stamping, so it can be trimmed with a die. Or it can be laser-cut for small batches. The function of the flat plate is to support the battery cell tightly and transfer the heat of the battery cell to the coolant.

Key take away:

The surface of the flat plate needs to be sprayed with epoxy resin with a thickness of 0.2mm to prevent insulation problems.

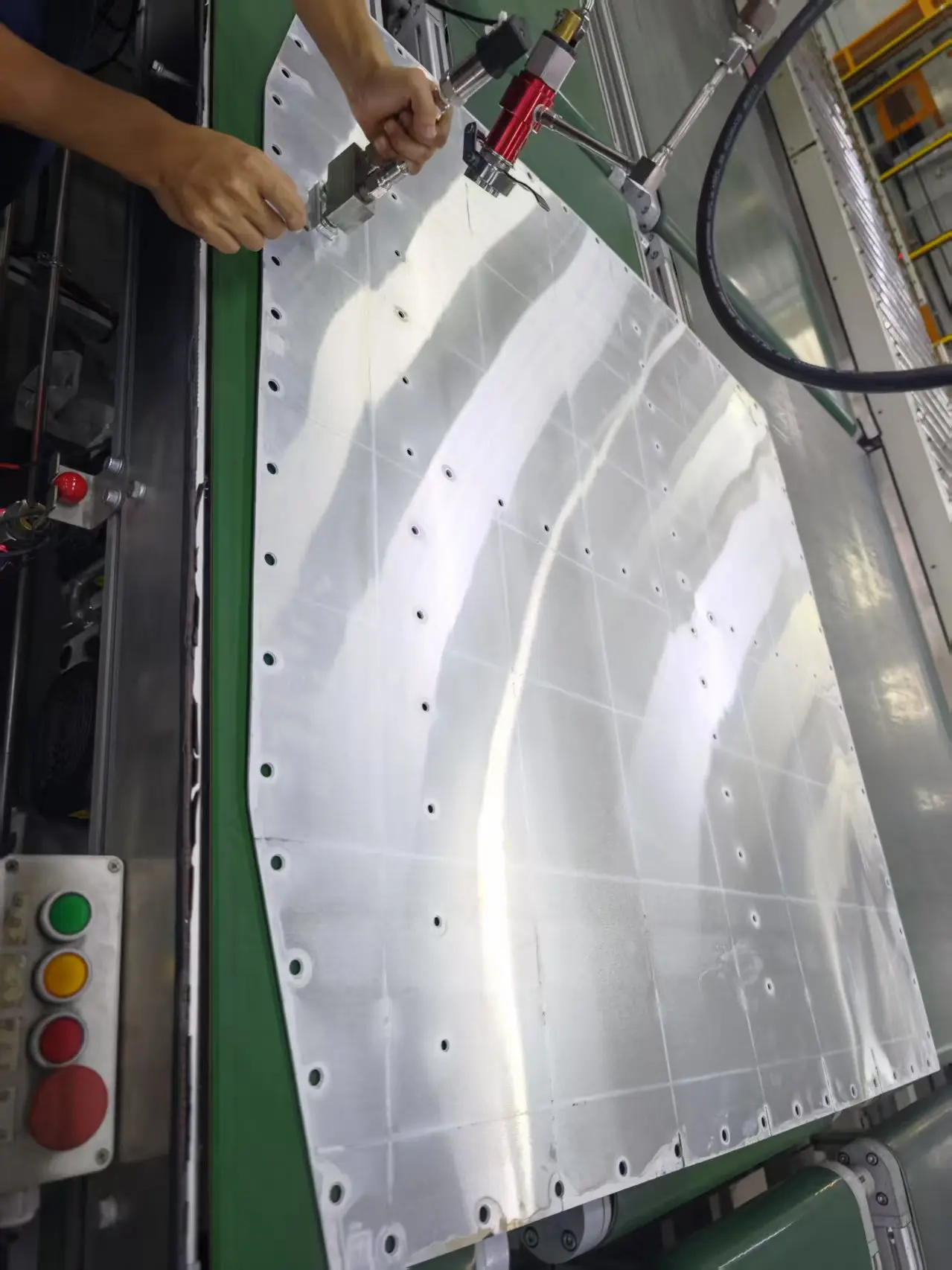

5.Channel plate for battery ESS cooling plate

Channel plates require a stamping die because of their channel pattern-drawing characteristics. For small batches, an ABS mold can be used, saving mold-making costs and ensuring a production time of less than 15 days.

Key take away:

At VehicleThermal, we can perform flow CFD simulation on designed flow channels for customers free of charge.

6.Aluminum bracket for battery energy storage cooler

Aluminum brackets mounting on manifold for positioning.This aluminum standoff bracket is made of aluminum alloy 3003 and is processed by CNC machining or stamping.

7.Flux roller coating on battery energy storage cooling plate

In order to remove the oxide layer on the surface of the channel plate, it is necessary to roll-coat a flux on the surface of the channel plate with a 4045/4343 composite clad layer. The flux is composed of potassium fluoroaluminate, and its purpose is to remove the oxide layer before the 4045/4343 composite layer is melted.

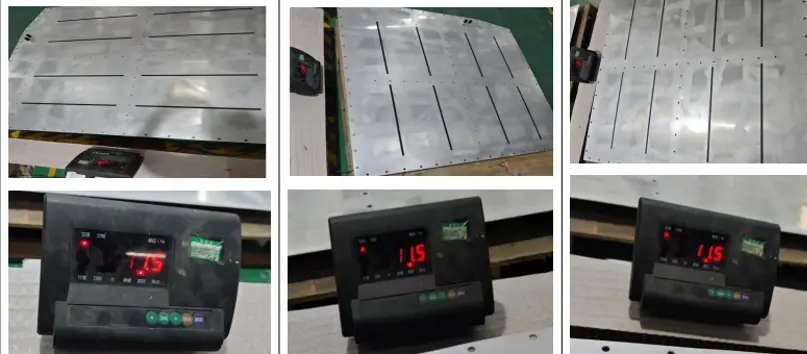

8.Battery energy storage cooling plate core assemble

First, the flat plate and water nozzle are riveted together. Then, the channel plate, which has been roll-coated with flux, is transferred to the top of the flat plate by a robot and installed in an overlapping manner.

After the core is assembled, it needs to be tox riveted. Then it is placed in the brazing fixture and prepared for the next step of brazing.

9.Brazing battery energy storage cooler in furnace

Brazing is performed in a tunnel furnace using a pre-set brazing program. The process includes degreasing, drying, brazing, cooling, and cold plate brazing before exiting the furnace. The entire process takes approximately 30 minutes.

10.Leak test on battery energy storage cooling plate

After the battery energy storage cooling plate is coming out from the furnace, it is transported to the helium testing station via a belt. For liquid-cooled cold plates, we use a leak test pressure of 250kPa and a leakage rate of 50Pa. The specific leak test requirements are mainly from customer requirement.

11.Quality inspection on battery energy storage cooling plate

Flatness is a key inspection parameter. For our battery energy storage cooling plate, we internally control the flatness in the free state to be below 15mm. Furthermore, we perform position and profile dimensional inspections to ensure that the customer’s installation dimensions meet the drawing requirements.

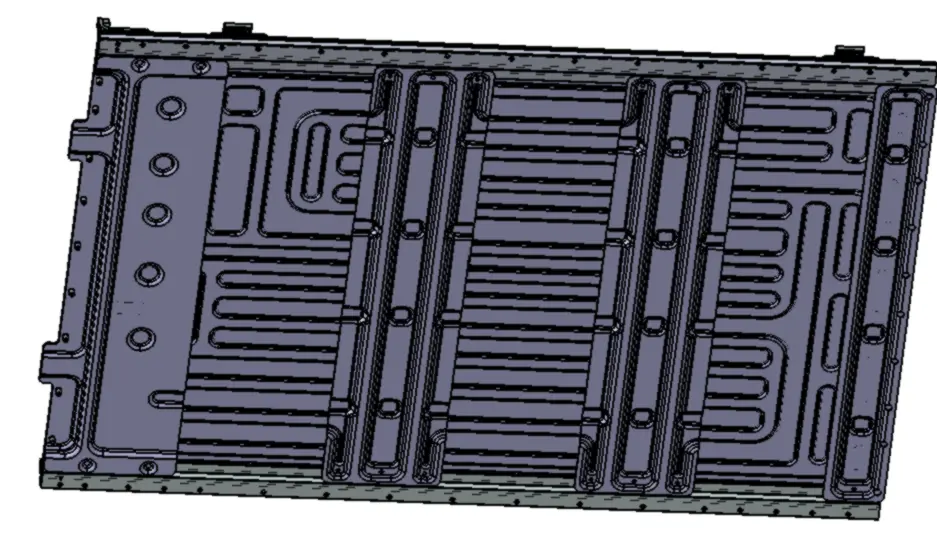

12.CAD design for battery energy storage cooling plate

We have a professional design team. Based on the cooling demand parameter, size and length boundary constraints input by the customer, we design the channel plate parts and the overall cooler 3D digital model and 2D drawing design for the customer. We will also provide the STP 3d and PDF 2D drawing to the customer for confirmation.

Key take away:

Our team has 14 years of design and manufacturing experience. We try to use existing parts as much as possible to save mold costs and quickly deliver design 3d digital models and drawings.

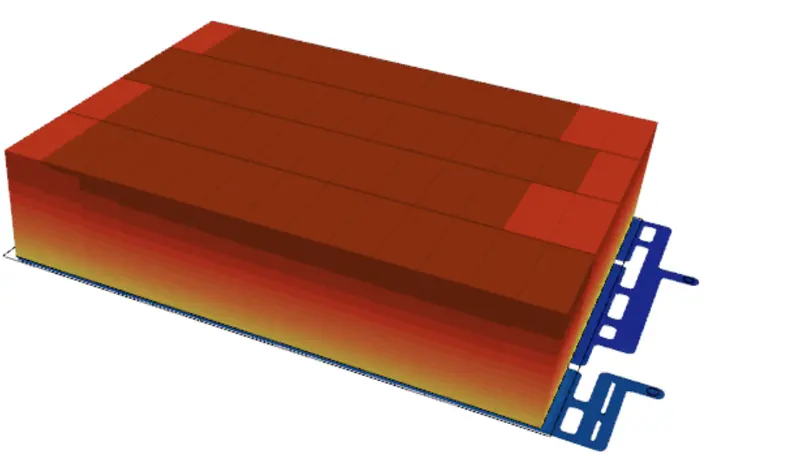

13.CFD simulation for battery energy storage cooling plate

In addition to manufacturing and digital model design, we can also assist customers with CFD simulation analysis of energy storage cold plates. With CFD simulation, we can help customers distribute flow and achieve optimal cooling effects.

More other type coolers find here:

Reviews

There are no reviews yet.