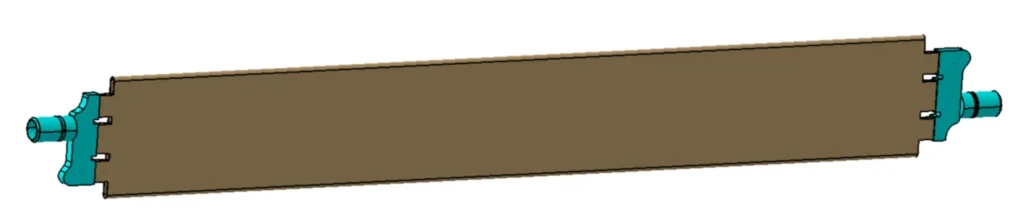

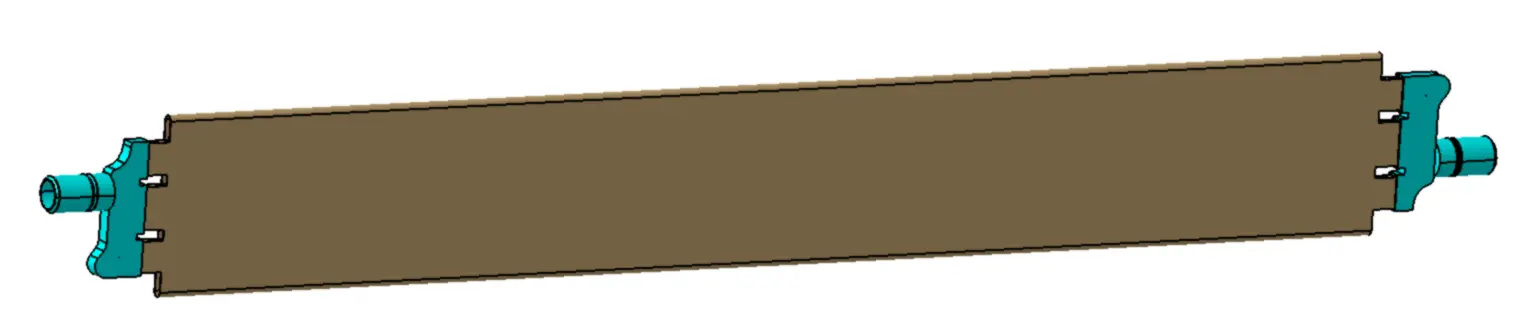

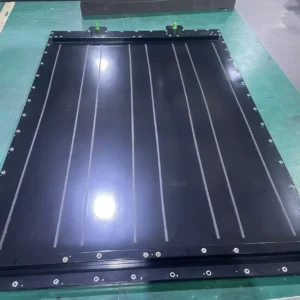

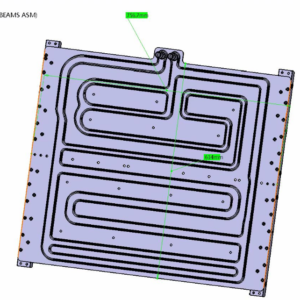

1.Example of custom microchannel cold plate

Microchannel cold plates can be used for direct refrigerant cooling, achieving high cooling efficiency. They can also be used in a 50/50 glycol circuit. The following are examples of custom micro-channel cooling plate we have provided to our customers.

2.micro-channel plate material

Typically, 3003-H112 aluminum alloy is used. Micro-channel tubes are extruded. Water nozzle are also typically made of 3003 aluminum and processed using CNC.

3.microchannel plate manufacturing process

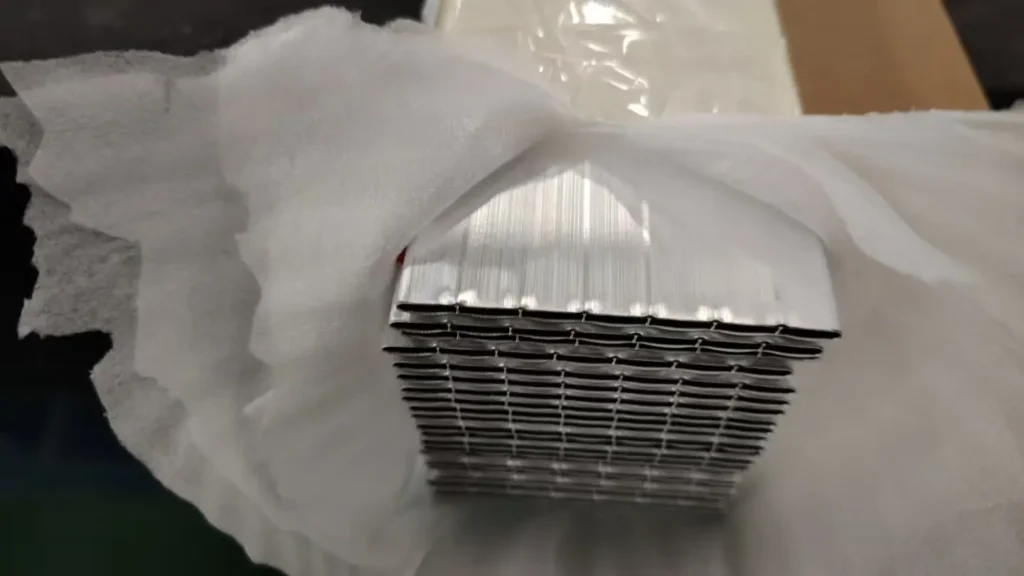

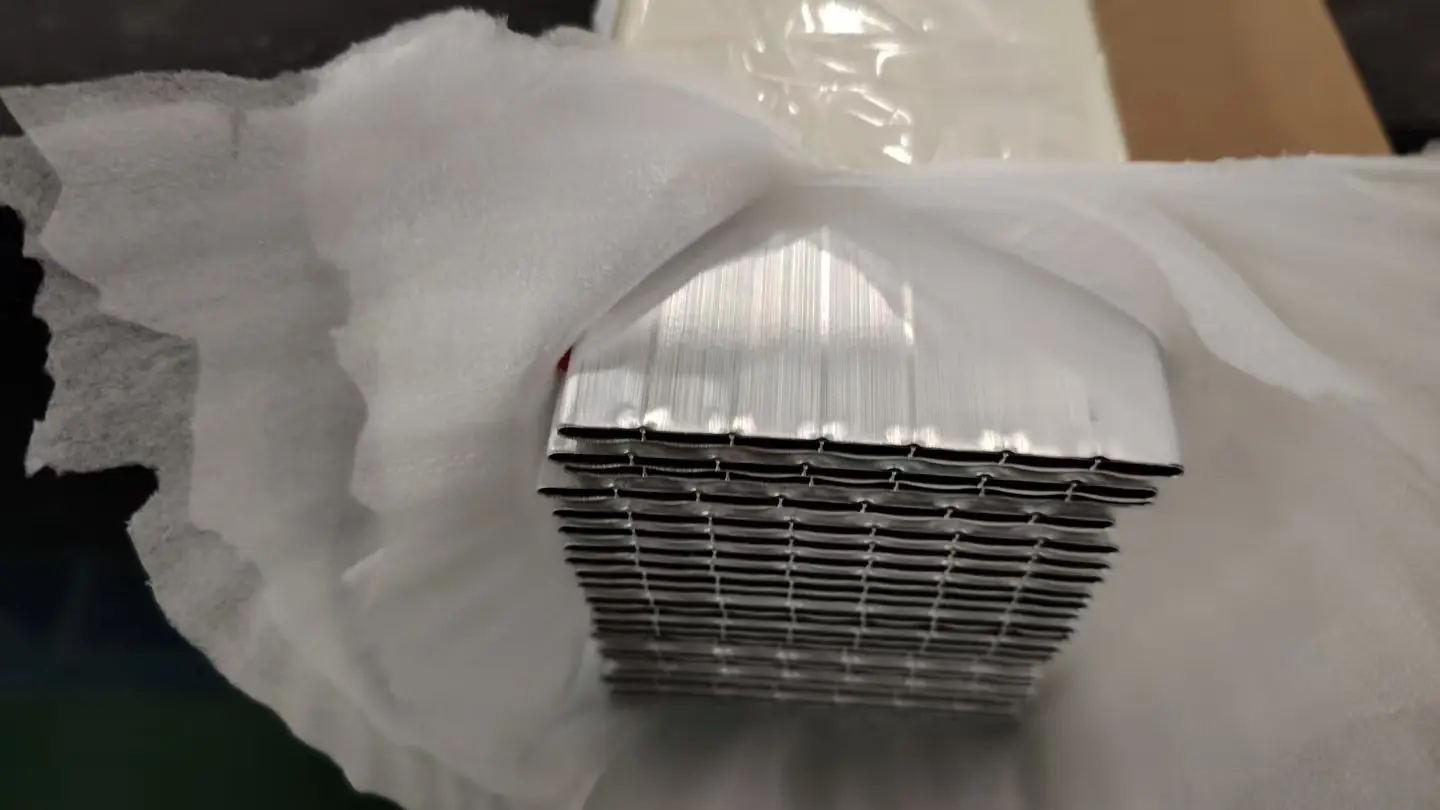

3.1 Micro-channel tube extrusion

Micro-channel tubes are produced by extrusion to produce long strips of tubes, which are then broken into certain length specifications.

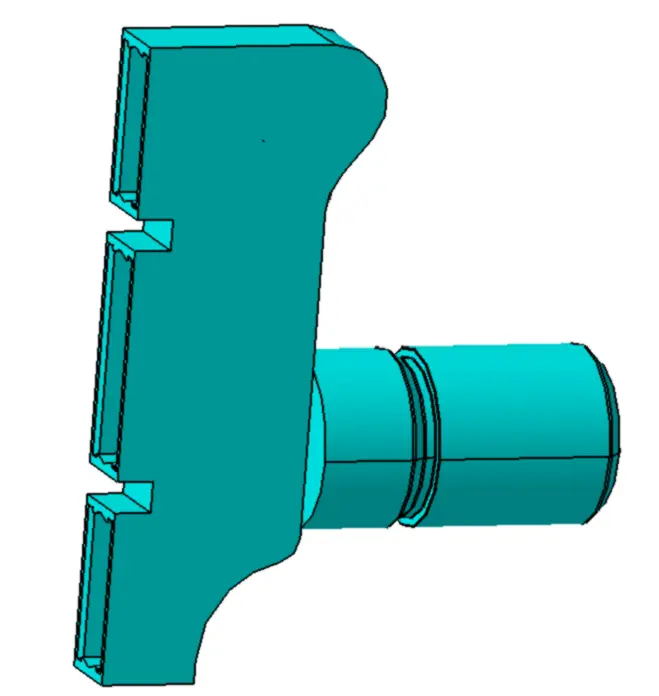

3.2 water nozzle CNC machining

machined according to the designed 3d model, and then remove burrs.

3.3 Assembling welding ring

The joint between the faucet and the Micro-channel tube is assembled with a welding ring.

3.4 Tunnel furnace brazing micro-channel cold plate

Brazing is performed in a tunnel furnace using a pre-set brazing program. The process includes degreasing, drying, brazing, cooling, and cold plate brazing before exiting the furnace. The entire process takes approximately 30 minutes.

3.5 Air leak test

Use air or nitrogen for testing, the test pressure is generally 250kPa, the leak detection time is 60s, and the leakage volume is less than 30Pa.

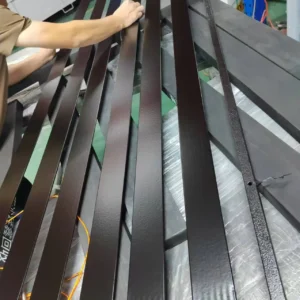

4 Powder spraying or PI insulation film

According to customer requirements, powder coating or PI insulation film is applied to the Micro-channel tube.

5 Quality inspection on micro-channel cooling plate

Carry out relevant drawing dimension inspection and flatness inspection.

Reviews

There are no reviews yet.