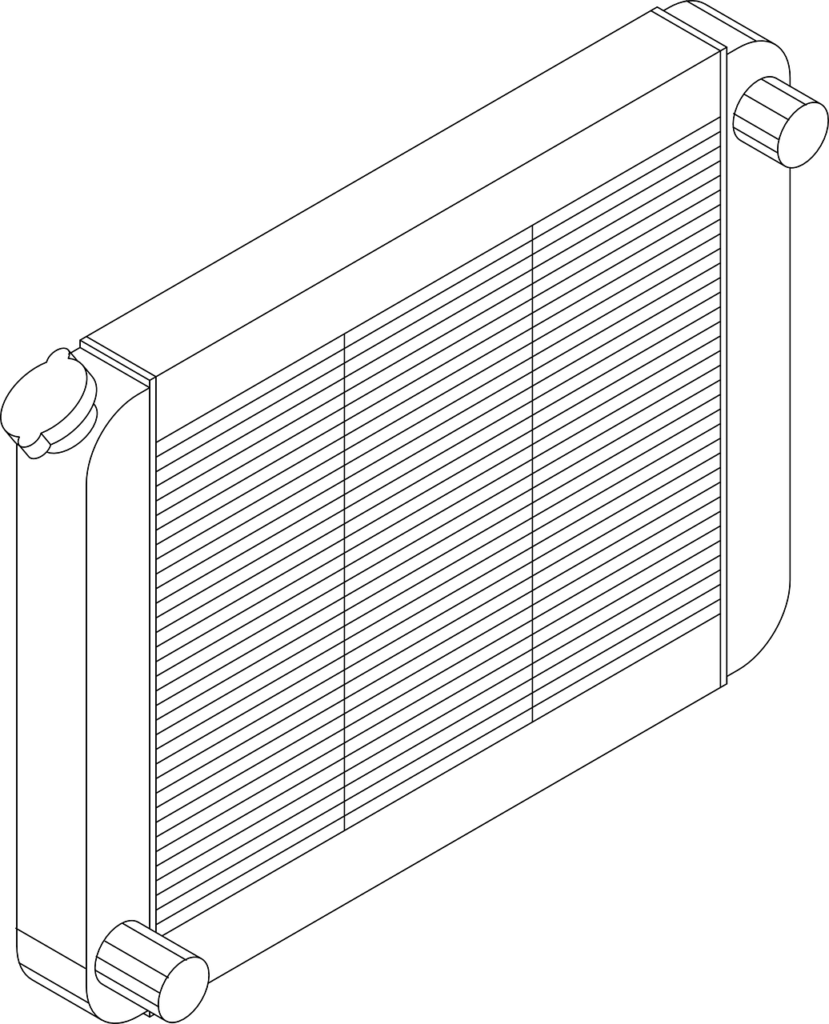

Heat Exchanger

Check with our engineer experts how to design and make mockup to validate your idea.

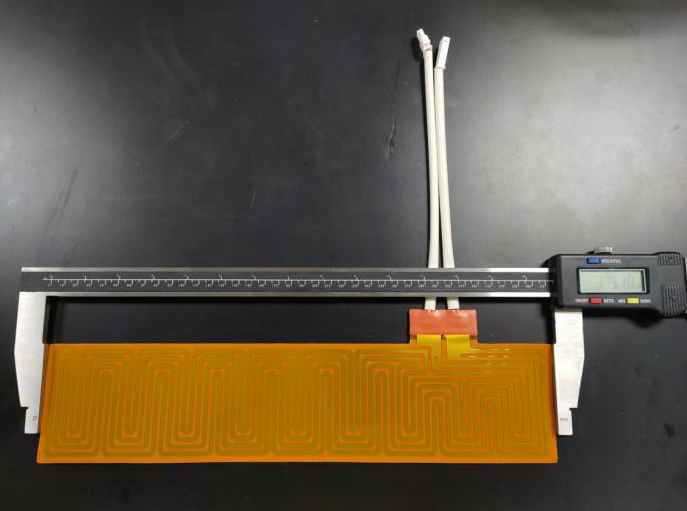

Heating film

The heating film is divided into PI, PET and silicone heating film, etc., which are directly attached to the surface of the battery for heating, and the heating rate is fast, generally reaching a heating rate of more than 0.8°C/min.

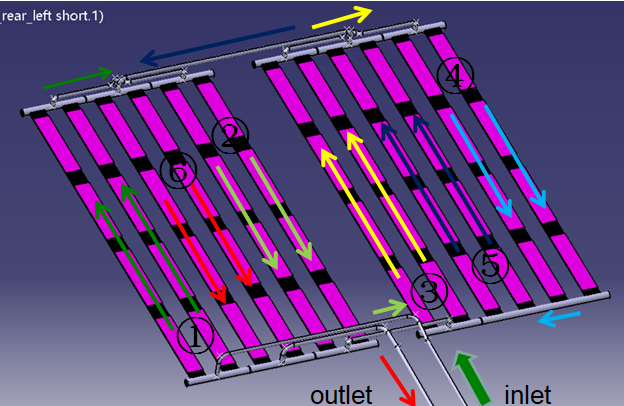

Battery cooler

Electric vehicle need battery cooler for thermal management. Battery water cooler and battery refrigerant cooler are the best choice nowadays.

Key point is how to design a battery cooler for the battery pack?

We have rich experience!

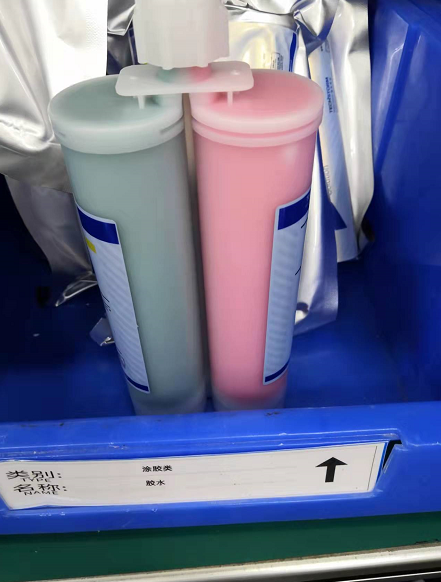

Glue

Thermally conductive structural adhesive is used for interface filling, reducing interface thermal resistance, and providing a certain bonding strength to the cell, especially for the current CTP, CTC, CTB and other new battery pack technologies.

Acrylic glue and epoxy glue are available.

Contact us for your application!

FAQ

Is thermal interface material a must for battery thermal conductivity?

Thermal interface materials, such as thermal pads or thermally conductive structural adhesives, can fill the gap between the cell and the water-cooled plate. This is a necessary component in order to reduce thermal resistance.

What is the temperature rise rate of the power battery heating film generally?

Generally at 0.3~1.2℃/min.

What is the material of the power battery water cooling plate?

The battery water cooling plate is generally brazed from 3003 aluminum alloy.

How much burst pressure can the power battery water cooling plate generally withstand?

Generally, it can withstand at least 8bar pressure without failure.

Types of power battery cold plates?

Power battery cold plate can be divided into coolant battery cooler and refrigerant battery cooler.

What is the function of some silicone foam in the power battery pack?

Silicone foam is used to seal the upper cover and the pack, and as an elastic support for the water cooling plate.

What type of glue is generally used in the power battery pack?

Generally, structural adhesives, thermally conductive glue, thermally conductive gap fillers and thermally conductive structural adhesives are used.

Is power battery simulation analysis necessary?

Simulation analysis must be performed to identify risks in advance.