1.Are side plates necessary for battery module?

Are side plates necessary for battery module? The answer is yes, as this aluminum side plates need to hold the battery cells firm inside the battery module. It’s a battery pack parts.

2.Battery module sideplate information

1.1 Inspection the raw material of Al6063

Material: AL 6063-T6+PET film

- The illumination position must be kept directly above the inspection area; the illumination should not be lower than 300lux, and local illumination can be added.

- Use a 10x magnifying glass to inspect the appearance of the plate of aluminum, and rotate the inspected product if necessary to meet the inspection needs of different areas.

- The tensile strength of the sideplate material is tested according to custom specification.

1.2 Inspection the raw material of PET

Keys take away:

- Under the environment of 23±5℃, the tensile strength of PET insulating film is ≥100MPa, and the elongation at break is ≥70%;

- Under the environment of 23±5℃, the bond shear strength of PET insulating film is ≥7MPa;

- The insulation resistance of PET film is ≥500M Ω@1000VDC, and the current leakage rate is less than 1mA@3800VDC;

- No damage to the appearance, no whitening, no bumps, no foreign objects and other undesirable phenomena.

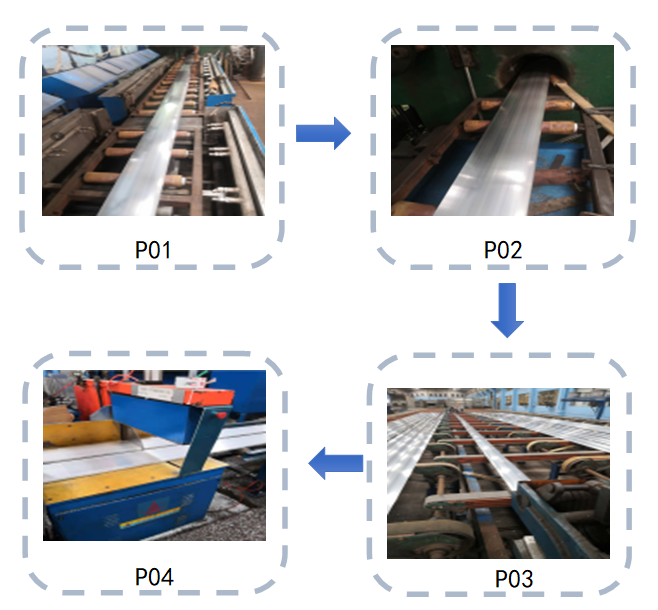

3.Al 6063 sideplate extrusion process

Check it out below how the aluminum sideplate extrusion.

process | P01 | P02 | P03 | P04 |

name | aluminum extrusion | Quenching | straightening correction | Piece cut |

4.Aluminum plate 6063 sideplate CNC machining

Aluminum plate with hole, milling holes on the planes and milling the external dimension features.

Aluminum extrusion plate, milling notched features at both ends of battery sideplate.

Aluminum alloy plate, milling the bead features.

Keys take away:

- Design the correct CNC program, move the machining tool accurately, and avoid the tool edge from scratching the surface of the product;

- Design fixtures correctly, make sure the clamp point not on the sideplate machining surface.

- After the product is processed, the appearance self-inspection is carried out, and the defects such as deformation and pits are isolated;

- It is processed by 3-axis/4-axis CNC machining center to ensure dimensional consistency and accuracy;

- Use special tool for processing;

- Use side push positioning + pressing claw to fix the product;

- Roughing and fine milling are used for product features to ensure product size;

- Confirm the burr surface according to the drawing and determine the clamping surface of the product;

- Confirm the product after processing and carry out burr height detection;

- Carry out cleaning and baking to clean the dirt and impurities on the surface to avoid flowing into the next process.

5.Al 6063 sideplate cleaning process

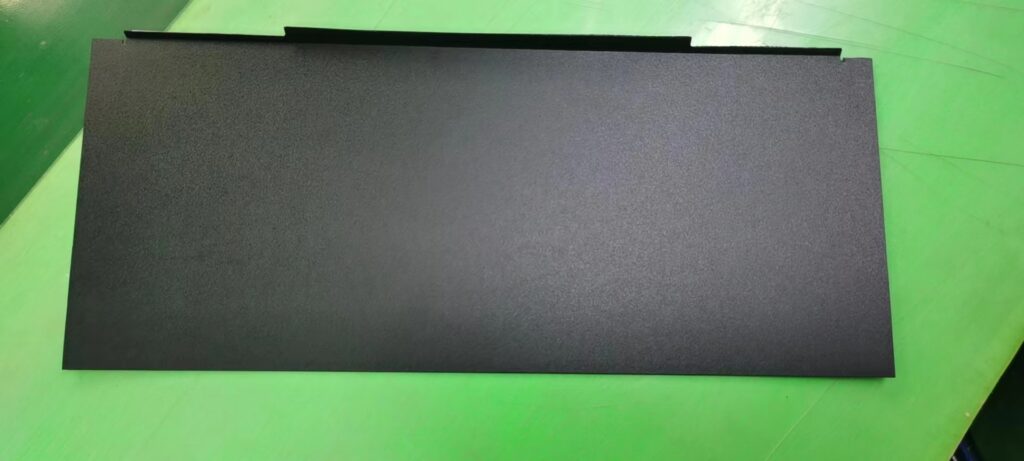

What I show in this article is a 5mm aluminum plate with PET film on the surface facing to the battery cells.

Sideplate aluminum plate 6063 appearance requirement:

- Keep it clean, without oil stains, oil stains, mold release agents, chips, burrs and other residues;

- Surface energy requirement ≥32mN/m;

- Burrs are not allowed on the mating surface and the appearance surface that will be in contact during the assembly process.

Technical control of battery sideplate appearance clean points:

- Reasonable DOE verification of equipment parameters;

- Design a special hanger, 360° cleaning without dead angle;

- Test the surface energy on the product surface with the Dyne pen Dyne ink corresponding to the surface energy;

- Carry out manual full inspection and manual deburring of the mating surface and the appearance surface that will be in contact during the assembly process.

6.Al 6063 sideplate hot pressing with PET

6.1 process of hot pressing

Picking, stacking, heat preservation, cold pressing, demolition, inspection, completion.

6.2 Sideplate dimension and appearance inspection after hot pressing with PET film

- The flatness of the hot-pressing fixture is less than or equal to 0.2mm to ensure that the pressing force of the product is balanced;

- The hot-pressing fixture maintains a high degree of consistency, and at the same time controls the high consistency of each set of hot-pressing fixtures after assembly;

- Stack the components in order from bottom to top according to the drawing to ensure that the stacking is correct, there is no omission, and there is no misplacement.

6.3 Peel strength of PET insulating film

- Confirm the corresponding insulating film model and specification, whether the insulating PET films meets the requirements;

- Carry out relevant DOE verification to confirm the hot pressing parameters;

- Effective and reasonable storage of PET insulating films to ensure that the insulating film of the laminated product is not abnormal

Keys take away:

Shear strength≥7MPa

Pulling strength≥7MPa

6.4 Properties of PET insulating film

1.Ensure that the PET insulating film is in the non-burr direction of the product to avoid damage to the insulating film;

2.Carry out insulation withstand voltage test on the products after hot pressing;

3.The storage racks used for material turnover are equipped with buffer pads to avoid product bumps;

4.Clean aluminum shavings on products and fixtures at the frequency specified in the SOP document.

1000VDC, resistance ≥1000Mohm;

4000VDC, leakage current≤1mA

Keys take away:

1 The test surface of the electrical test fixture completely covers the entire PET film, which can fully realize the overall electrical measurement of the film surface;

2.Design an electrical test fixture, which integrates insulation test and withstand voltage test;

3.Output the product insulation withstand voltage test chart to ensure that the test data is correct.

7.Package for battery module sideplate