A special feature of the Kirin battery is the liquid cooling plate design. All large surfaces of the battery cells in the entire package are cooled by liquid cooling plates.

The Kirin battery currently launched by CATL is the product of CATL’s third-generation CTP technology. Its volume utilization rate exceeds 72% and its energy density can reach 255Wh/kg. If installed in a vehicle, it can extend the vehicle’s range to over 1,000km.

Let’s compare two examples:

The volume utilization rate of Tesla’s 4680 is 63%, and the battery pack energy density is 217Wh/kg; the volume utilization rate of BYD’s new CTB blade battery is 66%, and the battery pack energy density is 200Wh/kg.

Qilin Battery Advantages:

1) Greatly improve safety, the micro-channel cooling plate has additional heat insulation function, which can achieve no heat diffusion;

2) Improve fast charging performance and double-sided water cooling of battery cells;

3) Improve the cycle life. The life of the battery cell will be shortened by half after tightening. That is to say, if it is relaxed a little, the cycle life can be doubled. The water cooling plate has an additional buffering effect.

4) Improved specific energy: The three-in-one water cooling, heat insulation, and buffering functions save a lot of space. Lithium iron phosphate can reach 160Wh/kg and 290Wh/L, and ternary high nickel can reach 250Wh/kg and 450Wh/L, which is 13% more power than 4680.

(1) Kirin Battery Innovations

1.1 Reconstruction of water cooling system

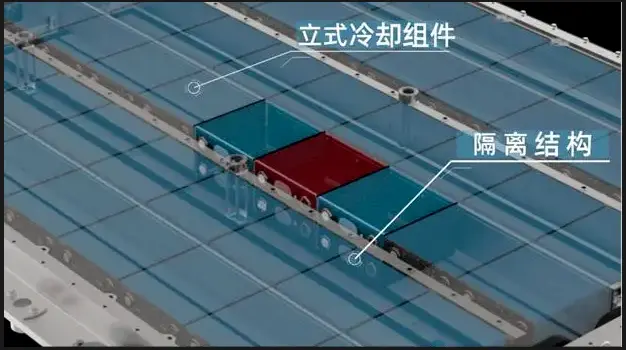

The Kirin battery uses an integrated multifunctional elastic interlayer. CATL integrates the horizontal and vertical beams, water-cooling plates and thermal insulation pads in the battery pack into a multifunctional elastic interlayer, combining support, cooling, thermal insulation and buffering functions into one. A micron-bridge connection device is built within the multifunctional elastic interlayer, which can freely expand and contract with the slight deformation of the battery cell during charging and discharging.

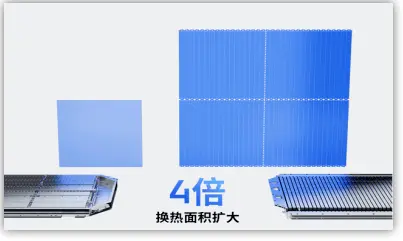

Kirin batteries feature a redesigned water cooling system, with a completely new layout. The system is now positioned between the battery cells, keeping them close to the cell’s surface. This shifts the traditional top-mounted cooling system to the side of the battery, increasing the heat exchange area by four times and cutting the cell temperature control time in half. CATL currently claims Kirin batteries can support a quick 5-minute hot start and a 10-minute fast charge to 80%.

1.2 The battery cells are arranged side by side in double rows back to back

More battery cells can be placed, which is more conducive to fast charging technology, while safety and volume utilization are greatly improved.

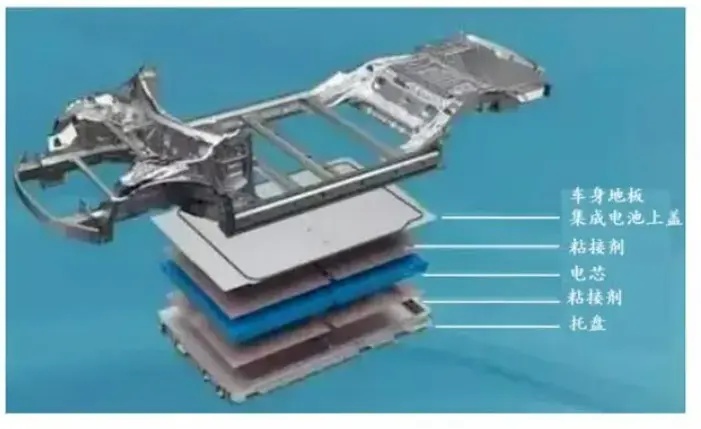

1.3 Inverted discharge of battery cells

First of all, the inverted cell design is adopted. The Kirin battery pack is an inverted battery, that is, the cell is inverted. After using the inverted cell arrangement, the Kirin battery pack allows the uncontrolled exhaust and the bottom ball hitting space to share, that is, what we often call battery exhaust and safety space to be integrated. In this way, from the perspective of the entire package space, 6% more space will be left for the battery cell, thereby improving the space utilization of the battery pack. In one sentence, it can be summarized as follows: The Kirin battery pack does not essentially change the internal structure and materials of the battery cell, but changes the battery system structure. Through the highly integrated battery system structure, the volume utilization of the entire battery pack is improved, thereby achieving an increase in energy density from the perspective of the entire package.

Keys take away: some challenges for this CTP3.0 Qilin pack

1.Structural parts are made of high-strength aluminum sideplate, extrusion and welding technology;

2.Water cooling plate design, water channel flow direction, water uniform flow and cooling capacity distribution;

3.The internal temperature of the battery pack is isolated from the external ambient temperature;

4.Electrical clearance, creepage distance, and insulation design matching;

5.Battery cell sampling and control accuracy, insulation design and testing, etc.

(2)CATL Qilin cooling plate design detail

The water-cooled plate has two layers of cooling channels, one inside and one outside, in a harmonica tube configuration. One of the outer and inner cooling channels is a liquid-cooled channel, and the other is a non-liquid-cooled channel (e.g., the outer layer is liquid-cooled, and the inner layer is air-cooled). Since the non-liquid-cooled channel is not filled with coolant, the channel wall can deform inward appropriately to absorb the expansion of the battery cells and prevent them from being squeezed and damaged.

(3)CATL CTP technology iteration

From the first generation CTP to the latest third generation Kirin battery, the battery pack volume utilization rate has increased from 55% to 72%.

CTP1.0: It uses a virtual large module, removes the module’s side panels, and replaces them with straps. The energy density can reach over 180Wh/kg. The representative model is the BAIC EU5

CTP2.0: Through the design of the lower box partition of the Pack, the end plate structure is eliminated, and it is compatible with NP technology (non-thermal diffusion technology) and AB batteries. The two end plates of the module are removed and the longitudinal and transverse beams on the box are used to replace the end plates. The energy density can reach more than 200Wh/kg, and the representative model is the NIO 75 degree.

CTP3.0: By placing the water-cooling plate on its side, it provides thermal insulation and enhances the system’s cooling capacity, enabling high-rate fast charging. This further eliminates the vertical and horizontal beams in the battery box, instead utilizing the plates between the two cells and the cell body to meet structural requirements. – Official Account – New Energy Battery Thermal Management – Energy density can reach over 250Wh/kg.

(4)CATL CTP3.0 VS Tesla CTC

First, to summarize in one sentence: Kirin battery is a technological iteration of highly integrated battery system, while Tesla 4680 is a technological iteration that changes the battery cell structure.

The Kirin battery’s cooling plate placement is similar to that of the Tesla 4680 battery, with a cooling plate sandwiched between the cells. However, the Tesla’s cooling plate doesn’t require support. The large cylinders provide more space for heat dissipation, and there’s an additional cooling plate above. Therefore, the Tesla CTC offers better heat dissipation than the Kirin battery. Combined with the full-tab design, it’s very conducive to fast charging, but space utilization is certainly lower than the Kirin battery.

(5)CATL CTP3.0 VS BYD CTB

BYD’s CTB utilizes a top-level battery direct cooling plate design and lacks inter-cell cooling. This makes its cooling performance inferior to that of the Kirin battery, hindering heat dissipation during fast charging. While BYD’s CTB retains the transverse steel beams that provide strength and rigidity, its structural strength is superior to that of the Kirin battery, but its volume utilization is lower.

(6)Kirin Battery CTP3.0 VS SAIC Cube Battery

The Magic Cube battery is a joint product of SAIC and CATL. The Kirin and Magic Cube batteries are highly similar, both using a vertical cooling structure. However, the Magic Cube battery adopts a dual-cell horizontal layout rather than the Kirin’s side-by-side layout. Without the expansion compensation sheet and insulating aerogel layer between the upper and lower cells, it cannot truly eliminate heat diffusion. Therefore, the Kirin battery has better heat diffusion control. The Magic Cube battery is thinner in the vertical direction, but its volume utilization rate is lower than that of the Kirin battery.

(7)sum of Qilin CTP 3.0 battery cooling plate

Cold plates replace the battery pack’s horizontal and vertical beams, and a double-layer cooling channel design is superimposed, simultaneously providing support, water cooling, thermal insulation, and buffering. Furthermore, the battery cells are arranged sideways in a double-row, back-to-back configuration, accommodating more cells and significantly improving overall safety, fast-charging performance, cycle life, and specific energy. Kirin batteries represent a key approach for the company to further enhance battery performance through structural innovation within its existing prismatic battery technology. Iron-lithium batteries combined with Kirin batteries can compete with blade batteries, while high-nickel ternary batteries combined with Kirin batteries can compete with 4680.