CATL qilin CTP 3.0 is a latest battery technology.Recently, CATL released the new NP3.0 (No Propagation 3.0) technology platform, which achieved battery safety upgrades through multi-layer innovations in chemical systems, structures, system design and control strategies. The NP3.0 platform is now actually used in Qilin battery packs. Below I will get you an overview of CTP 3.0 in battery cell insulation and anti-expansion design.

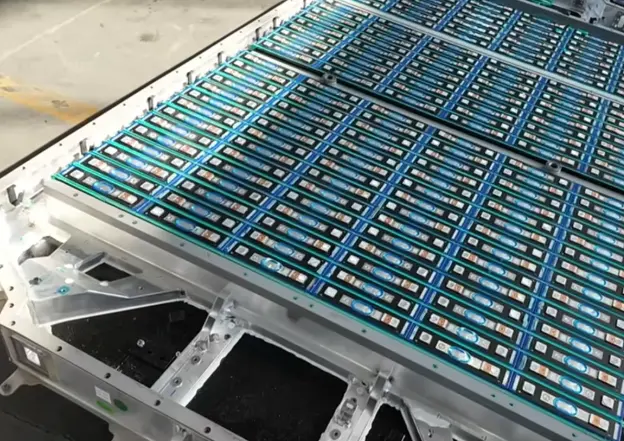

1.overview of the qinlin ctp 3.0 pack structure

The Qilin pack design is NP3.0, meaning that even if a battery cell experiences thermal runaway due to electrolyte leakage or arcing, it will not cause thermal runaway of the entire pack, effectively preventing heat spread. CATL says their battery technology as offering best-in-class safety performance.

2. Electrical insulation and heat insulation design for qilin ctp 3.0

Take the Qilin battery pack of Li Auto MGEA as an example.

The large surface of the battery cell is directly attached to the water-cooled tube plate, and the two are electrically isolated by pasting insulating paper to prevent the battery cell blue film insulation from failing and contacting the metal water-cooling plate.

Aerogel is used between the sides of the catl qilin battery lfp and the liquid battery cooling plate. See more for the qilin cooling plate design.Since the sides are not in contact, MGEA’s aerogel appears to be a simple PET film without a circular silicone frame.

Between the sides of the battery qilin lfp cells, MGEA does not use aerogel, but instead uses silicon carbide rubber.

In contrast, the Xiaomi SU7 qinlin battery pack uses aerogel, which is 0.6mm thick and has a maximum temperature resistance of 1000°C.

3.CTP 3.0 Qilin battery cell anti-expansion design

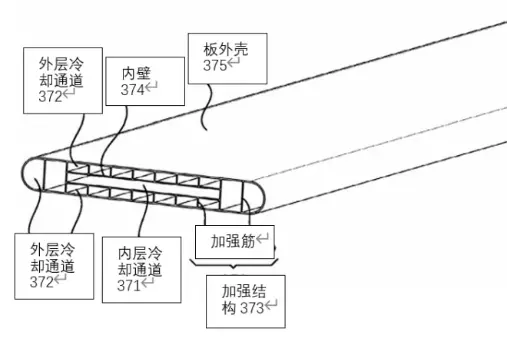

CATL’s patent CN202210401809, “Water-cooled plate assembly, water-cooling system, battery and its housing, and electrical device,” explicitly mentions the idea of a water-cooled plate absorbing battery expansion force by deforming the non-liquid cooling channels within the water-cooled plate structure. The water-cooled plate assembly’s harmonica tube sheet is internally equipped with outer and inner cooling channels.

The main channel for coolant flow (see image below) is equipped with multiple support ribs. These ribs strengthen the channel walls, preventing deformation and leakage caused by internal coolant pressure or external battery cell expansion, thereby ensuring stable heat dissipation.

However, in the actual disassembly of the Li AUTO MEGA Qilin battery pack, it was found that the harmonica tube plate after cutting did not have an inner channel structure as in the patent.

I guess that the internal structure of the patented cooling plate is too complicated, and the double-layer channel needs to be extruded through composite extrusion molding. The finished product processing has high requirements on the aluminum plate material, mold precision and welding technology, and the OK rate in mass production is hard to achieve.

This harmonica tube plate structure, thanks to its inherent ductility, allows for limited deformation. Combined with the reserved expansion space and the buffer design of the manifold, it can easily absorb expansion forces, thus allowing it to be used in mass-produced products. However, ensuring the heat dissipation and sealing of the liquid cooling plate while also absorbing the expansion force of the battery cells presents a significant challenge for the harmonica tube plate.

Learn more for the PV testing for battery cooling plate here.