How to calculate pressure drop?Pressure drop is crucial in plate heat exchangers.The pressure drop of a water-cooled plate influences the selection of the system’s water pump and also affects power consumption. While maintaining a certain heat exchange output, it’s desirable to minimize the pressure drop. The following example,I want to present a battery cooling plate to explain how to calculate pressure drop. It’s a real case in our factory.

1.Introduce of the battery cooling plate model

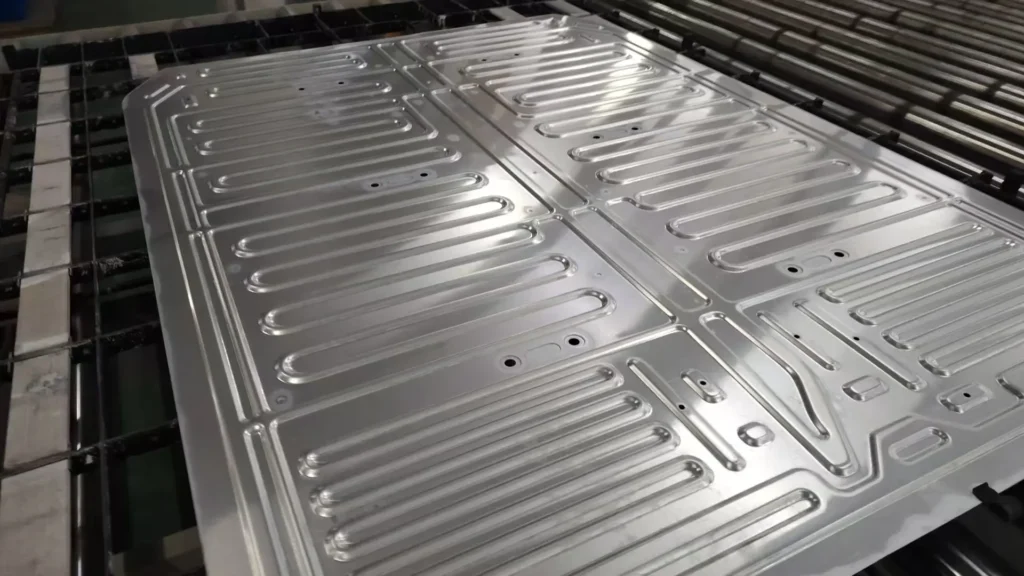

It’s a stamped water-cooled plate model, mass production in 2024.The material is 3003MOD, and the flux roller coating process is used. In previous articles, we have also introduced that flux roller coating can improve internal cleanliness compared to flux spraying, thereby reducing the pressure drop of the water-cooled plate.

2. Cooling plate internal volume extraction

Before performing pressure drop calculations and simulations, we need to extract the internal volume.Please keep in mind,base on our simulation model calibration, for extracted fluid domain, we do not simplify the R angles, and the simulation model fully retains all detailed features. That will help to improves simulation accuracy.

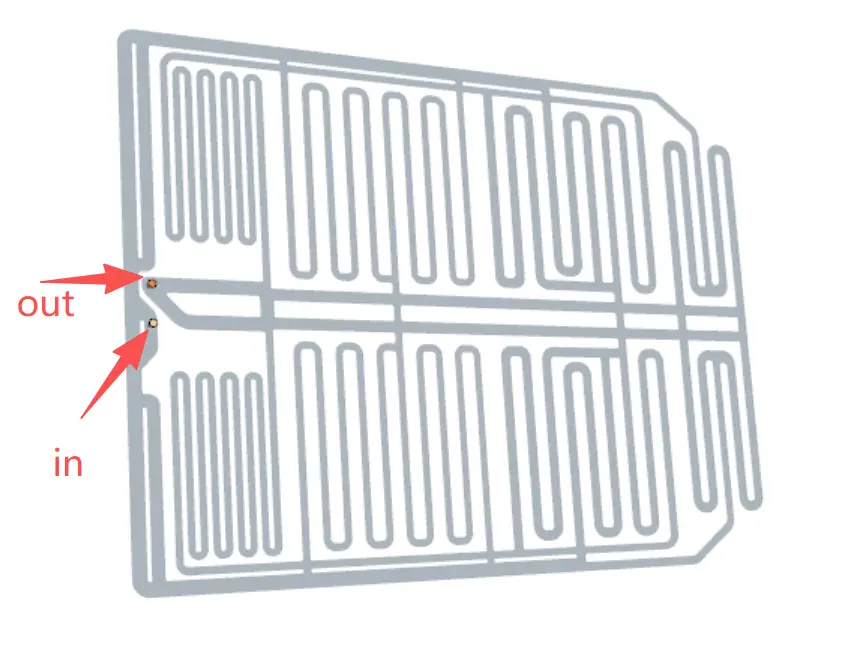

3.Assign inlet and outlet port domains

According to the customer’s digital model design, before generate the mesh, it is necessary to specify the inlet and outlet to prepare for the next step of mesh generation.To calculate pressure drop precisely, we can’t reverse inlet and outlet port.

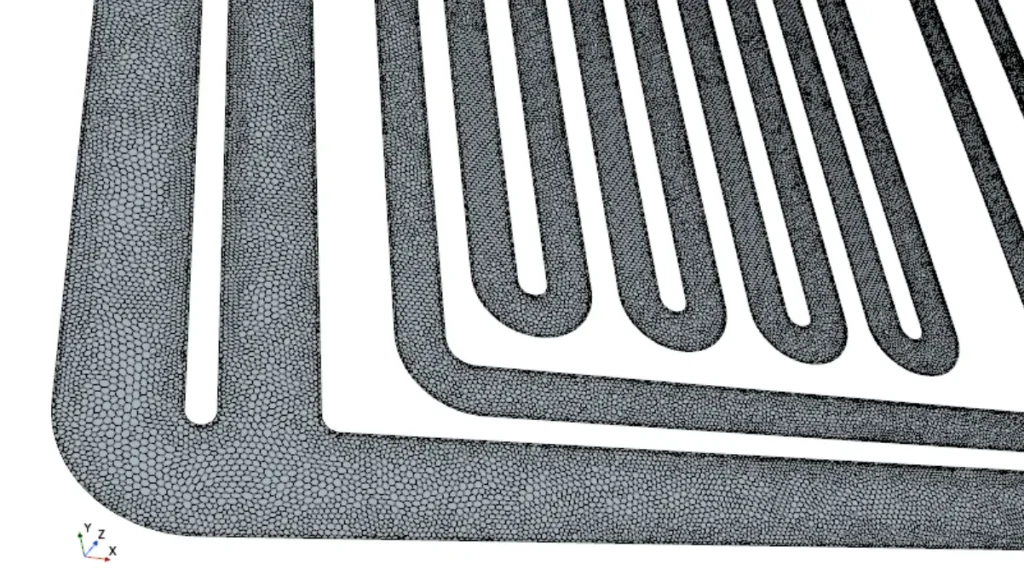

4.Mesh generation on battery cooling plate

Before to calculate pressure drop, we need to perform mesh settings and generate cooling plate face mesh and solid mesh in star ccm+ software.

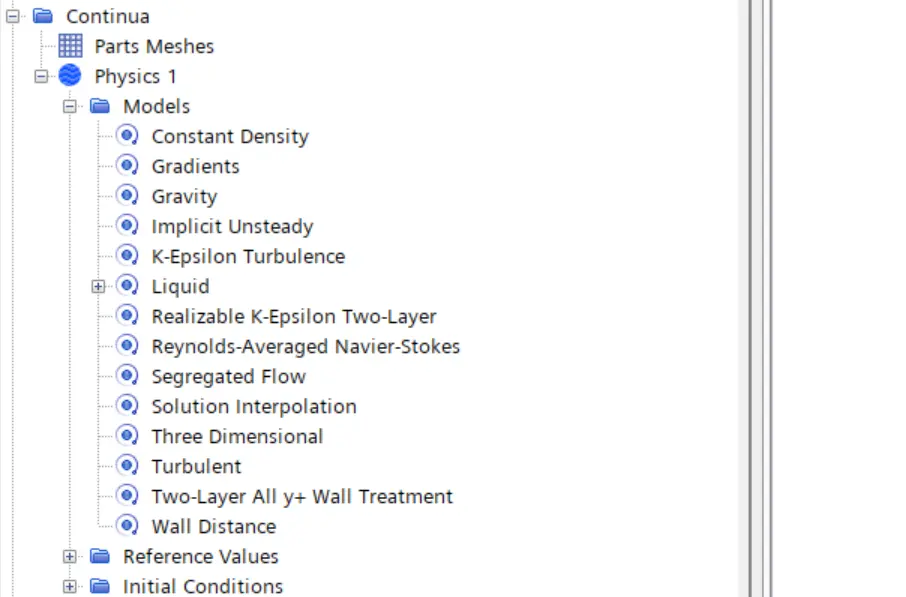

5.Physical domain settings

In the STAR CCM+ software, set up the physical domain for fluid properties. This involves selecting the corresponding simulation model, as shown in the following screenshot.

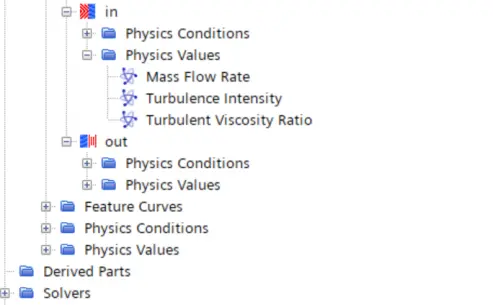

6.Simulation pressure drop boundary Settings

Set the inlet and outlet parameters, such as inlet flow and outlet pressure.

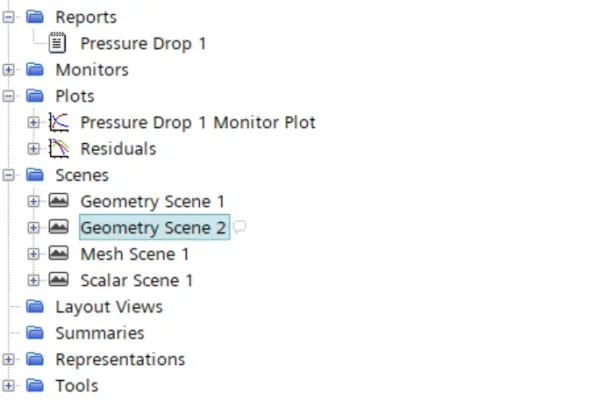

7.Report, plots and scenes settings

Use the STAR CCM+ software to generate pressure drop reports and plot settings. In the scenes section, set up scalar and velocity cloud maps to obtain simulated pressure drop and velocity cloud maps.

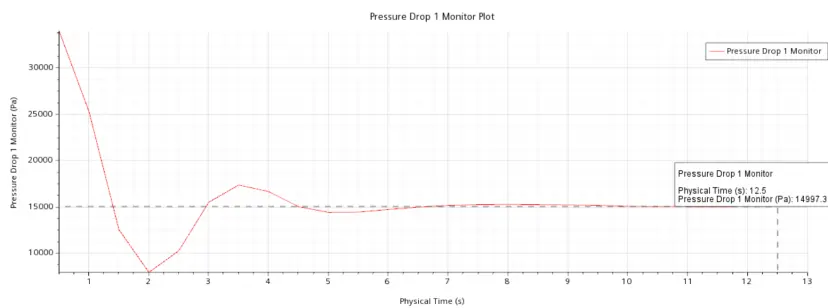

8.Simulation pressure drop results show

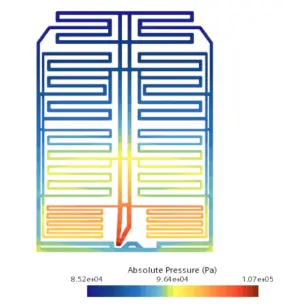

This case simulation is based on the operating conditions of 25 degrees Celsius, 50% 50% ethylene glycol, and 10L/min. The simulated pressure drop is 15KPa.

The figure below shows the pressure drop contour diagram of the mid-section.

By comparing the measured pressure drop of the cold plate with the actual pressure drop test (see our other blog post), we found that the simulation error was within 7%, indicating that our simulation model can accurately predict the pressure drop of the battery cooling plate.