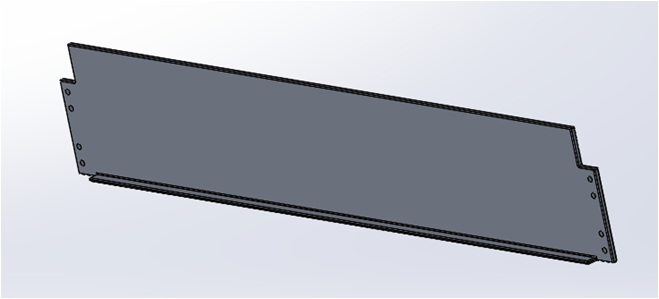

1.Battery module PC film information

Material: polycarbonate, with one side Polished or Velvet optional

2. TYPICAL PROPERTY VALUES FOR BATTERY PACK PC SHEET

| PC sheet PROPERTY | Test Method | Units | Value |

| Specific Gravity | ISO 1183 | g/cm3 | 1.2 |

| Water Absorption Equilibrium,24 Hrs | ASTM D570 | % | 0.35 |

| Tensile Strength | ISO527 | Mpa | ≥60 |

| Tensile Modulus | ISO527 | Mpa | ≥2400 |

| Flexural Modulus | ISO178 | Mpa | ≥92 |

| Vicat Softening Temperature | ISO306 | ℃ | ≥140 |

| Thermal Expansivity | ISO11359 | /℃ | ≥6.5*10^-5 |

| Permittivity | IEC60250 | ≥3.1 | |

| Voltage test | IEC60243 | KV/mm | ≥30 |

| Volume Resistivity | ICE60093 | Ω.cm | ≥10^16 |

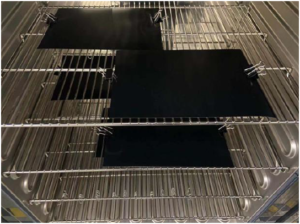

3. Battery module PC film low temperature test @ -20 degrees Celsius

3.1 Test conditions:

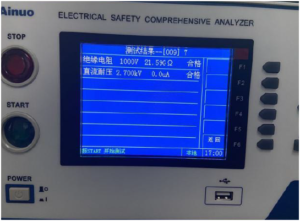

Place the sample in the environment of -40C for 24 hours, take it out, and test the electrical properties after standing at room temperature for 1 hour. Insulation resistance test: test voltage: 1000VDC, test time: 60s Withstand voltage test: test voltage: 2700VDC, test time: 60s

3.2 Acceptance criteria:

- No obvious change in appearance, no cracks and other defects

- Insulation resistance>500MΩ@1000VDC

- Leakage current <1mA

3.3 Test results:

No obvious change in appearance, no cracks or other defects observed.

Insulation resistance: 11.11GΩ

Leakage current: 0mA

4. PC film low temperature test @ 120 degrees Celsius

4.1 Test conditions:

Place the sample in an environment of 120C for 24 hours, take it out, and test the electrical properties after standing at room temperature for 1 hour. Insulation resistance test: test voltage: 1000VDC, test time: 60s Withstand voltage test: test voltage: 2700VDC, test time: 60s

4.2 Acceptance criteria:

- No obvious change in appearance, no cracks and other defects

- Insulation resistance>500MΩ@1000VDC

- Leakage current <1mA

4.3 Test results:

No obvious change in appearance, no cracks or other defects observed.

Insulation resistance: 21.59GΩ

Leakage current: 0mA

Reviews

There are no reviews yet.